Aluminum: Aluminum substrates involve another approach. A chromate conversion coating is frequently utilised to enhance adhesion and corrosion resistance, specifically for architectural or out of doors programs.

Generally speaking all thermosetting powder formulations incorporate close to the binder resin and cross-linker additives to help move out and levelling and for degassing. Prevalent is using stream promoter wherever the Lively component—a polyacrylate—is absorbed on silica as copyright or as masterbatch dispersed inside of a polyester resin as matrix.

Will not touch the article when it is actually faraway from the oven following curing till it is extensively cooled.

Social login does not get the job done in incognito and private browsers. Be sure to log in along with your username or e-mail to carry on.

When making use of powder coating or regular paint utilizing a spray gun, a large amount of material is likely squandered as “overspray.” This refers to the portion of fabric dispensed with the spray gun that never ever reaches the meant area.

The powder might be formulated to obtain different gloss concentrations, textures, and colors, making it perfect for the two useful and aesthetic applications.

Thermoplastic coating features better efficiency than thermoset. It is also fewer dense than thermoset powders. Thus You should utilize much considerably less powder to attain a similar complete. Thermoplastic powders will also be thicker and more flexible than thermoset powders.

Whether for purposeful or attractive applications, powder coating delivers an answer for improving the effectiveness and visual appearance of countless items and structures.

A coating method for flat products that applies powder with a roller, enabling relatively significant speeds and accurate layer thickness in between 5 and one hundred micrometres. The base for this method is traditional copier know-how.

Powder coatings include no solvents and release little or no degree of volatile natural and organic compounds (VOC) in the ambiance. So, there is absolutely no want for finishers to purchase high priced air pollution control devices.

Discharges across tiny distances between charged surfaces and floor can comprise enough Electrical power to ignite the powder becoming sprayed within the gun, more emphasizing the safety aspect.

Soon after coating, curing normally takes put – this is most often attained by means of significant warmth. Sometimes, the metallic portion is heated prior to powder software.

Removing of oil, Filth, lubrication greases, metal oxides, welding scale and many others. is vital ahead of the powder coating method. It can be carried out by several different chemical and mechanical methods. The las vegas powder coating selection of the tactic depends on the dimensions and the material of the part to become powder coated, the sort of impurities to become eradicated plus the performance prerequisite from the concluded products.

As a result, picking a powder coating demands thorough thought of those variables making sure that the coating fulfills the specific demands and sought after results of the venture.

Barret Oliver Then & Now!

Barret Oliver Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Michael Bower Then & Now!

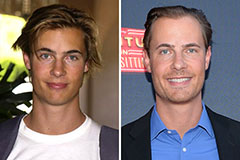

Michael Bower Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now!